THE RIGHT TOOL MAKES ALL THE DIFFERENCE

If it has to be . . . RAISED, LOWERED OR MOVED.

and you don't know how… - we do!

Rent or Buy our Products

CALL US NOW 866-522-5464

Our Full Range Of Hydraulic Jacking Products

RENTAL • SALES • SERVICE

RENT OR BUY OUR PRODUCTS

CALL NOW: for Information: 866-522-5464

As well as Jacks and cylinder jacks, WB Equipment maintains in-house all the tools and products you may require for any jacking job you may have. Our list includes Flange Spreaders, Hydraulic Torque Wrenches, Nut Splitters, Hydraulic Presses Hydraulic, Manual, Air & Electric Pumps, Strand Jacks, Synchronous Lifting Systems, Stressing Jacks, Air Lifting Bags, Screw Jacks, Bottle Jacks, Hydraulic Cutters, Pullers, Loadcells and Custom made Equipment like Power Units and Custom Made Jacking Systems.

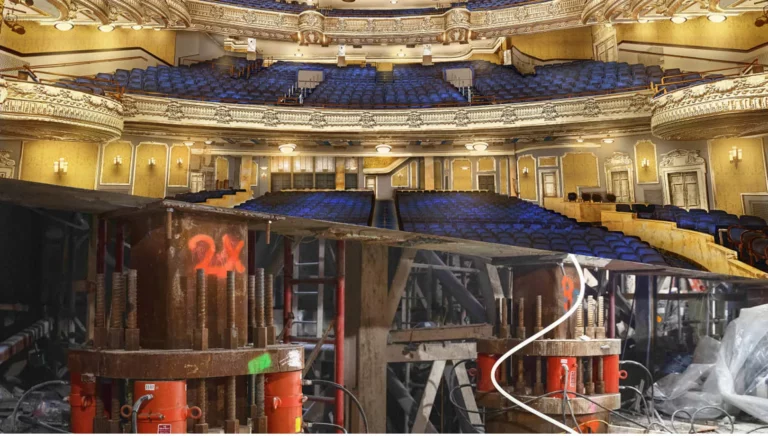

WB EQUIPMENT CORP. PROJECTS

PRODUCT CATEGORIES

Most Popular Hydraulic Jacking Products

hydraulic jacks and jacking systems

wb specialized equipment

hydraulic pump products

* Next Day Delivery * CALL 866-522-5464 NOW!

WB Equipment is a specialized equipment supplier to industry and construction, with emphasis on custom hydraulic and pneumatic systems. We specialize in both Synchronous and Simultaneous Jacking Systems.

These systems are used to jack, hoist, lift or move almost any type of structure. Applications include bridge raising, bridge rolling, pipe jacking, pile testing, pre-stressing post tensioning, house moving and foundation repair and underpinning.